How To Draw A Sewing Pattern

The Nuts of Patternmaking for Fashion

Plumbing equipment for Wearing apparel Design - Section one: Introduction to Patternmaking

Welcome to Section ane of a Costless five role serial, Fitting for Apparel Design. In this series we will cover everything you need to know to fit your garment samples and create a perfect fit for your brand. If yous'd like to read more than about what is included in this series, delight take a look at this overview of Plumbing equipment for Apparel Design.

In this first section we will be covering the basics of patternmaking and how this knowledge will allow you to create the perfect fit your apparel brand. Patternmaking is an essential skill to learn and understand in order to fit garments appropriately. Patternmaking tin be quite complicated! In this section nosotros volition be walking through the basics of patternmaking so that you can have a great foundation to start from. I hope to create a more than in-depth patternmaking tutorial in the future, just this is a comprehensive overview of the essentials!

This post contains affiliate links. Learn what that means for you and for me .

Larn in whichever way best suits you!

Lookout the video below or scroll down to read the full post.

Follow me onYouTube for more educational videos!

PATTERNMAKING

First off, let me clarify that patternmaking can exist spelled with or without a space (ie. patternmaking / blueprint making). I learned to write it without a space, but other professionals include a infinite! It's really upwardly to yous how y'all'd similar to write it and there is no "right" way.

What is patternmaking?

Patternmaking is the foundation of a garment. To put it very simply, patternmaking is plotting the measurements (or specs) to create a newspaper template of a garment. That template is so used to cutting fabric to be sewn into a garment.

Typically, patternmakers will beginning with a sloper and adjust it to brand specific manner patterns. A sloper is a simple pattern with no seam allowance, style lines, or ease. One time the garment is spec'd out in paper format (patterned) information technology tin can be made into a muslin sloper. From there, adjustments are made to the fabric prototype (muslin) to perfect the fit. Those adjustments are then transferred back to paper and trued for the finalized design.

Why Practise I need To understand patternmaking for my fashion business organisation?

"But Natalie, I'm not a patternmaker and I don't have any intentions of being ane! Why practice I need to know this as a make owner?"

I'yard glad you asked! If you are non intending to make your own patterns and you are a part of the fashion manufacture, I nonetheless encourage yous to read through this information. In this case, the more y'all know almost patternmaking the easier it volition be for you to accurately fit your paradigm garments when they come up in. You will also be able to communicate the changes you need from the factory much better! With this knowledge you volition save a ton of time and money through the evolution process.

Glossary

Here is a quick list of defined terms and tools you may demand for this tutorial.

Patternmaking terms

-

Grain - The direction in which the yarn of a fabric is woven or knitted.

-

Bias - A line that intersects with the warp and weft at a 45˚ angle. Used when maximum stretch is needed for draping.

-

Seam Allowance - The allotted textile beyond the pattern for stitching garments together.

-

Style Line - Seams that give the garment shape such equally a princess seam.

-

Ease - The amount of space between the trunk and the garment (tightness vs. looseness).

-

Sloper - A simple pattern with no seam allowance, style lines, or ease.

-

Muslin Sloper - A garment synthetic from the sloper design with muslin cloth. Used to perfect the fit of a pattern.

-

Trueing - The blending and straightening of pattern lines for the purpose of creating correct seam lengths.

-

Block - An unchanging base pattern that provides consequent residual and key measurements as a starting bespeak for garment evolution.

-

Fit Intent - How a garment is meant to fit in terms of ease over body, finish apply, and comfort.

-

Design Intent - The intended silhouette, shape, proportion and design elements of a garment.

-

Selvage - The finished edge on the lengthwise grain of woven fabric.

-

Bust Point (pivotal signal / noon) - The noon of the bust as designated on the pattern.

-

Dart - A cut-out in a pattern used to create shape.

Patternmaking Tools

-

Vary Form Curve (or sometimes written Variform) / Hip Curve - Used to shape and alloy patterns, typically at the hip and waist.

-

French Curve - Used to shape and alloy patterns, typically at the neck and armhole.

-

Measuring Record - Used to measure out curved shapes and forms.

-

Quilting Ruler - Clear ruler to see the lines of the pattern and make quick adjustments.

-

Tracing Wheel - Transfers design to paper or muslin using carbon newspaper.

-

Awl - Used to add a hole in the design for marker details, like darts.

-

Design Paper - Gridded paper for patternmaking.

-

Notcher - Notches the pattern to transfer design lines such as sprint legs.

-

Design Tape - Special record that will not rip the pattern paper when removed. Used when making adjustments to the pattern.

-

Design Weights - Holds the pattern when tracing or transferring to cloth.

How to create a design

To go along it uncomplicated, let's walk through how to create a unproblematic front bodice pattern piece. At present, there's several ways to approach this. First, you will need to decide who yous are creating the design for. Is this for a specific person? A size for your fashion brand? Or exercise you beloved the fit of a retail sample you own? For this example, nosotros're going to be making a front bodice blueprint for a size in our size prepare for our make. I already have a size chart made and therefore know the size for this example pattern. If you lot need help creating a size nautical chart checkout this tutorial, or yous tin buy pre-made size charts as a role of the Tech Pattern DIY Kit.

If yous are referencing a specific person or a retail sample (garment) y'all will need to measure the person or garment. I have a full tutorial on how to measure out a garment. If you're measuring a model (or yourself) I advise picking up Patternmaking for Fashion Pattern by Helen Joseph-Armstrong. This volume walks you through how to plot points based on your measurements. It has worksheets, calculations, and a step-by-step procedure to create patterns! If you're interested at all in creating your ain patterns, I highly propose this book.

Ok, at present that we know who the pattern is for we demand to make up one's mind what blazon of garment this is. The type of garment, blueprint intent (fit), and cloth play a huge role in determining how you will plot your pattern. For this instance we are going to exist making a very unproblematic bodice (front simply) sloper. The design intent is fitted and the fabric is woven (no stretch).

To help you sympathise this a niggling bit better let me use this example:

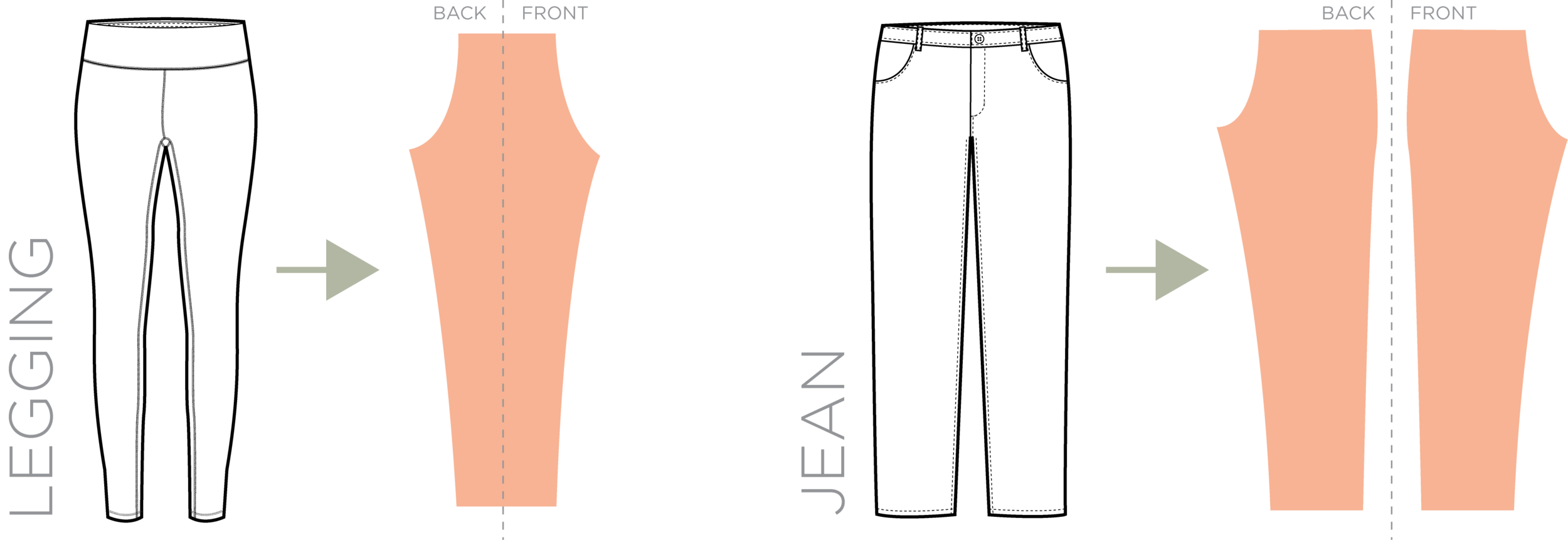

Imagine a woman owns a pair of jeans and a pair of leggings, both garments fit her well, but when off of her torso the leggings appear much smaller. That is considering the design intent of the leggings is bodycon and the fabric is a knit (stretch) and the blueprint intent of the jeans is fitted, only the fabric is a woven denim (non-stretch). Therefore, the patterns for the leggings and the jeans are very different. Here'southward an example of what those patterns may look similar:

Here'southward the info we've gathered and so far for our example:

-

WHO: Medium (Ladies) - from our size chart

-

GARMENT TYPE: Bodice (we'll be patterning the front but)

-

DESIGN INTENT: Fitted Sloper

-

FABRIC: Muslin (woven - no stretch)

Ok, and so at present that we know who we are making the pattern for, what our pattern intent is, and our material choice we can brainstorm plotting our points. For this part of the tutorial please reference reference the video higher up to meet how I manually plot a pattern. The manual patternmaking section starts at 07:17.

Remember, this is just one piece (front end) of a total tiptop! Now that you lot know how a design is built, you can encounter how changes to the design of a garment in a fit session will effect the design. We'll be talking more than nearly mutual fit bug, how to fix them, and what that means for the pattern afterward on in this series.

patternmaking principles

In that location are 3 principles to be aware of when making edits to the pattern for ameliorate fit:

-

Sprint Manipulation - How the location of a dart is inverse inside the pattern. A dart can be transferred to any other point effectually the pattern (in relation to the pivotal indicate - bust betoken) without changing the fit of the garment.

-

Adding Fullness - Applies when the excess fullness needed is greater than that of the dart. The slash and spread technique (beneath) is used to add fullness where desired.

-

Contouring - Absorbing the dart excess into mode lines to create a contoured silhouette.

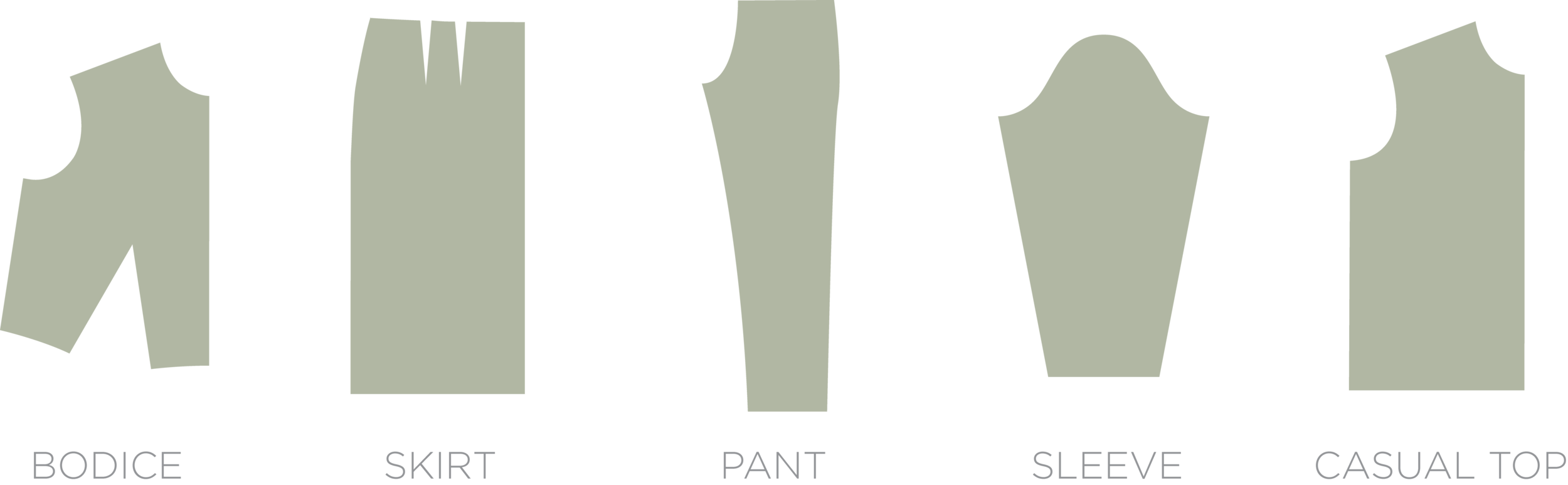

Identifying common Pattern Shapes

Being able to quickly identify pattern shapes while working with your factory or patternmaker is essential for clear communication! Most of the patterns you will see may vary slightly from these outlines, but as long as you sympathise the foundational shapes you'll be able to identify what type of garment pattern you're looking at.

Pattern Manipulation Techniques

When using a sloper to create a stylized pattern, we oftentimes will add or change design lines. This ways that we demand to transfer the shaping (darts) to our new desired way lines. There are ii manipulation techniques:

-

Slash and Spread - The new design line is cutting and spread open up to create a new dart, while the original dart is closed. The working pattern is contradistinct.

-

Pivot - The pivotal point (bust point or dart point) stays stationary. The pattern is traced and pivoted to close the old dart and create the new sprint. The working design is not altered.

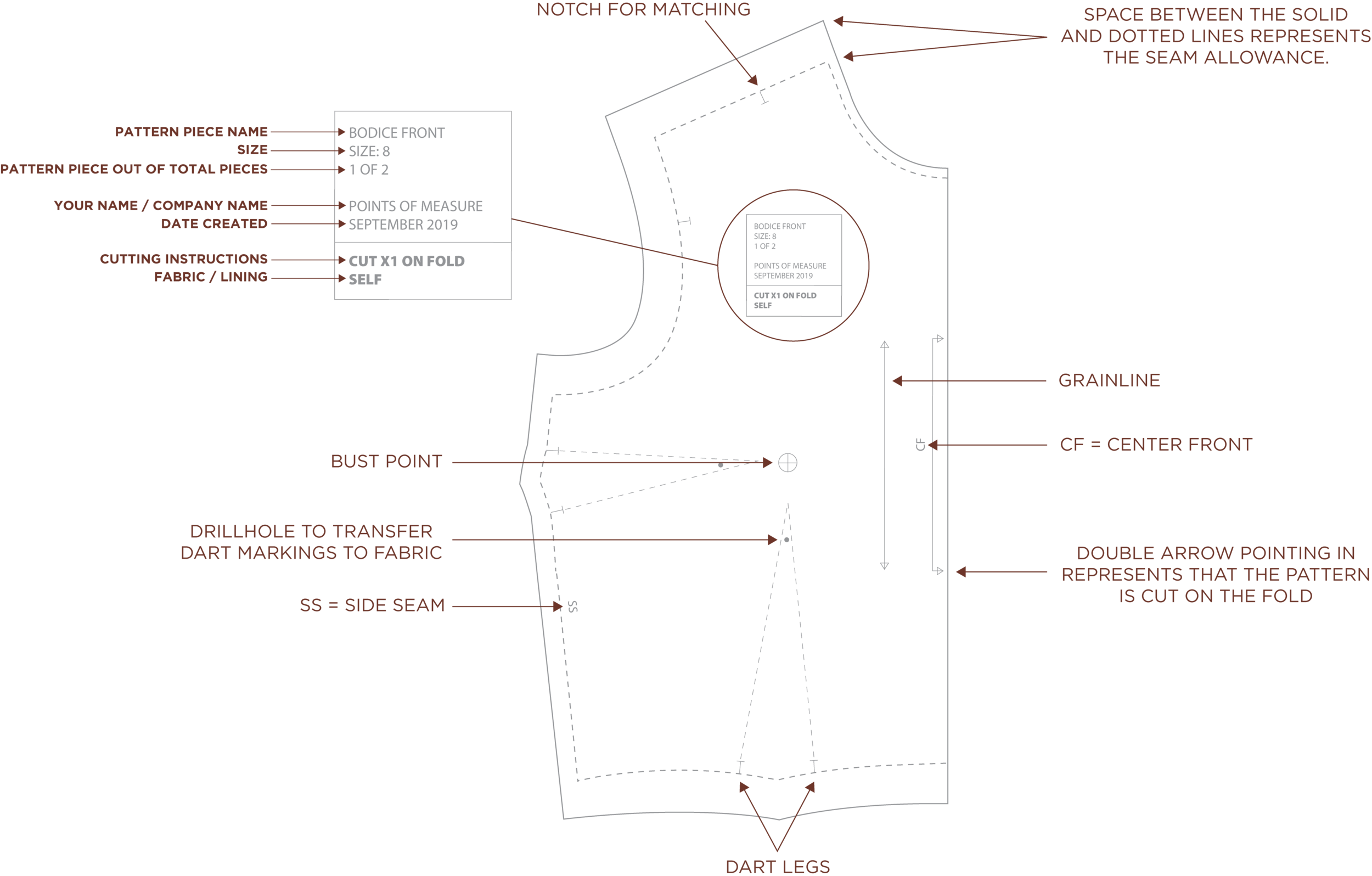

Design Labels and Markings

Hither is a basic diagram to show you how patterns are commonly marked and labeled. Depending on the design, you may meet some other more specific markings, but this will give you a practiced foundation for understanding the markings of a pattern.

DIGITAL PATTERNMAKING

What is Digital Patternmaking?

Digital design making is accomplished in much the same style that traditional (newspaper) patterns are created. Patternmaking software takes the specs from your Tech Pack, plots the points, and creates a digital pattern. This tin can be manipulated and printed from the design software. If you are creating your own patterns, you can too digitize them by using a program you probably already have - Adobe Illustrator (read more on this in Method two below).

Digital Patternmaking methods

Method ane: CAD Pattern Software

Pattern software is the most common manner you volition encounter digital patterns being created. Factories use this method when creating the blueprint, based off of your tech pack specs. To put it merely, the mill will enter your requested specs into their software system, and then the figurer does its magic! The points are plotted, using advanced calculations, into the requested pattern size. In well-nigh cases, some adjusting volition need to occur in order for the design to be correct. This is why it's important to include tolerances in your tech pack (besides as for construction and cutting variables).

Did you lot know that CAD software is available to the public? You don't have to be a large factory to access these programs! This allows freelancers and small-scale design firms to utilise the same tools every bit the factories that they work with. For case, Xochil uses StyleCAD and a plotter to create and print her patterns. Xochil, The Chicago Patternmaker, was kind enough to lend us her expertise in CAD software and printing! Accept a look at her method for developing and printing digital patterns:

Xochil Herrera Scheer, The Chicago Pattern Maker

"Now that your pattern is made in CAD, in order to cut and sew a prototype in your fabric, you lot need to print it out! Some people may exist familiar with downloadable habitation sewing patterns which can exist printed at habitation on standard paper, then taped together, or equally a big format PDF which can exist printed at a impress shop such as FedEx. When I first purchased my CAD system I did not purchase a plotter at the aforementioned fourth dimension due to the expense, and then I started out past exporting my design files to Adobe Illustrator, and then printing at FedEx from a PDF. This added a lot of time in the extra steps I had to do to prepare the files, also as fourth dimension and expense of printing at FedEx multiple times a week. After 6 months I decided to make the investment into a plotter. I researched a few dissimilar companies and types of plotters to run across what would work best for my needs, deciding to buy from Velocity Plotters since they were very helpful and service oriented (despite being located across the country from me), and I'm glad I did. They helped me to remotely ready and configure the plotter to my CAD organization (I utilise StyleCAD), but it'south also compatible with multiple file types including vector-based PDF documents. It as well works with other CAD systems in case I ever want to switch programs in the future, or I tin print files from colleagues hands likewise.

There are unlike newspaper widths and features available, since I work on the product evolution side, my needs are primarily for printing markers for prototyping, and not for production, so I opted for a 49" broad plotter which fits into my home role. For production, plotters go upwards to 72" so that they tin can accommodate wider width fabrics; for this I send jobs to my trusted colleague OnPoint Patterns. Other times a client's manufactory may take the capability to receive pattern and marker files and volition plot themselves or use an automated cutting system.

When I'thou gear up to plot a pattern, I prepare the sample marking in my CAD programme and impress to a PLT file. So I load that into my plotter's program and print it out. The marker is either placed on top of the fabric and cutting together (newspaper and fabric layered, this is how you would cutting in production), or if the fabric is slippery I will cut out the pattern in paper kickoff, and so place on fabric and cut the fabric layer alone.

Digital pattern making and markers accept the wonderful power to be edited hands, just as well to exist used and printed anytime y'all need, and by dissimilar people in your supply chain.

Although at that place is paper consumption, the paper is easily recyclable, and is more authentic over time than tracing from an oak tag pattern, specially in production.

Having a plotter in house means being able to epitome more than chop-chop, and is an important asset and tool for digital design makers."

Method 2: DIY Digital Patternmaking

CAD programs and plotters are essential tools for the development of RTW collections, just may not be the most affordable option for home sewers and freelance designers. Well, I'm here to tell you at that place'due south another option. Yous can create your ain patterns in Adobe Illustrator. Yup, y'all heard me right! AI is technically a CAD plan, but is much more attainable. In fact, I bet that you probably already have it on your computer if yous're in the style industry. And if you've read my series, Introduction to Technical Flats, and then you already have all the skills you demand to apply AI to create patterns.

Methods for Digitizing Your Pattern in Illustrator

-

Create your pattern by hand (paper) and so scan it into your computer and trace the epitome using Illustrator (or other digital art program). Only make sure that your image is not being scaled or your measurements will exist skewed. This is a neat method if you are draping your patterns and desire to save digital versions.

-

Or (my favorite) plot your points for your pattern directly in Illustrator.

How to Create a Design in Illustrator

You lot will follow the same steps as we did for our paper pattern to plot your points! I've included a walkthrough of how I create my digital patterns in Illustrator in the video above. This office of the tutorial starts at 19:23 and is a continuation of the manual pattern walkthrough earlier in the video.

Here are some helpful tips you may non know near:

-

Make apply of the rulers, grid, and guides to help you plot your points.

-

You can prepare your certificate to inches (or centimeters, etc.) under File > Document Setup.

-

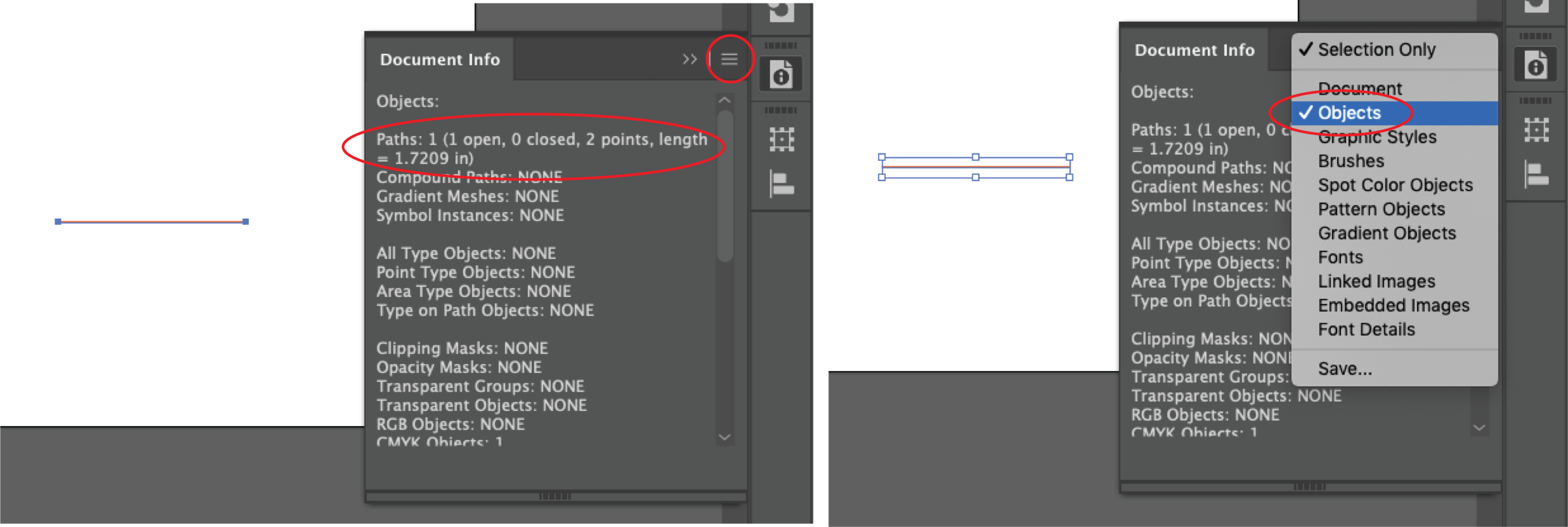

Y'all tin see the length of any line by going to Window > Document Info. In one case you lot see the Document Info window, you lot tin use the card dropdown on the superlative correct to admission it's options. Select "Object" and when you click on your path you will run across the first line shows the length of your path in inches.

-

Or y'all can purchase plugins like Vector Scribe that evidence you the length of a line as you lot draw it.

-

Note that new versions of Illustrator now include a line length indicator as you draw! This negates needing to utilise a plugin or using the Document Info window and makes the process much easier. I talk more about this in the video.

-

Y'all tin create your own curved rulers equally objects! Or accept advantage of my pre-fabricated digital rulers that are a part of the Plumbing fixtures DIY Kit (more on that beneath). Update: the Fitting DIY Kit has now been split into multiple options (beneath). You tin can now purchase the digital bend rulers separately or as a part of the Foundation Pattern Kits.

-

Employ layers to your advantage! They are not bad for separating reference patterns and/or photos. Later in the serial nosotros will impact how important layers are for creating nested grades.

-

You can use Illustrator'due south calibration and blend tools to grade your digital pattern up or downwardly, make elementary edits, and scale it for a half class virtually instantly! More on this when we get to the digital grading department of this series.

-

Use Illustrator's Starting time Path to automatically add together seam allowance.

-

You can specify the altitude an object moves when using your arrow keys. I have mine set to 1/8" to make piece of cake adjustments. We'll talk more about this in the grading department of this series.

Printing Your Digital Patterns at Habitation

-

Salve and print equally a PDF. You can besides impress directly from Illustrator.

-

Double cheque that your printer is not scaling your patterns. Cheque them again in one case they are printed!

-

Set your printing borders to every bit small as possible.

-

Do not overlap your artboards! Simply line them up edge to edge and place your pattern on top. I've saved my pattern printing setup as a template to easily utilise anytime.

-

Add a coding organisation to each folio. I code mine by row (letters) and column (numbers). This has saved me many times when my printer skipped a page or printed out of club!

-

Record row by cavalcade and true up any missing lines (each page will have about an 1/8" edge). Then cut out of the larger canvas. Double cheque your scale again!

-

You can also cut apart your patterns (digitally) to fit on individual pages, so cut out, match up, and tape together. I like to add together a star on the cutting line to make certain I'm matching it up just right.

Now available

FITTING TOOLS

You may also like:

Source: https://www.pointsofmeasure.com/tutorials-education/the-basics-of-patternmaking

Posted by: boothbyfirad1964.blogspot.com

0 Response to "How To Draw A Sewing Pattern"

Post a Comment